TRW Series

Table-top NC Machining Center that Brings Your Ideas to Life

Table-top NC machining center specialized for resin machining.

With air chuck and separate control panel design,

it serves a wide range of applications from educational institutions to R&D facilities.

Wood

*For aluminum machining, please see the TLM Series.

TRW Series Track Record

Widely adopted by customers in educational institutions and research facilities

Extensive Adoption in Education and Research

Our products have been adopted by numerous customers, primarily in educational institutions such as universities, technical colleges, and vocational schools, as well as corporate R&D departments.

With the concept of “bringing ideas to life”, we have earned high praise for our Table-top NC machining center that enables rapid prototyping from concepts.

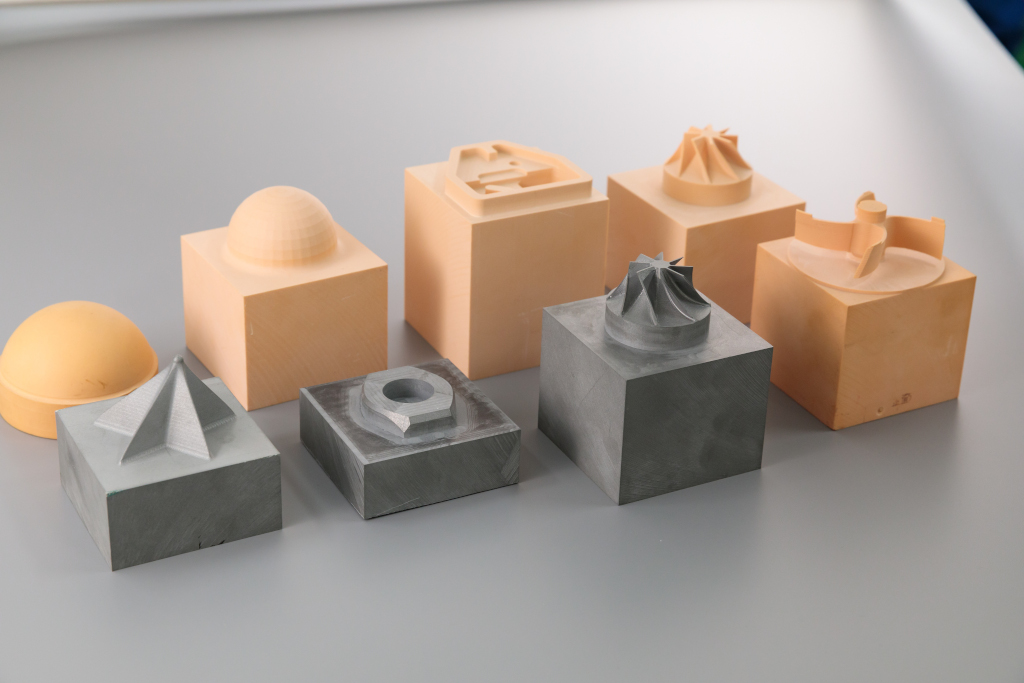

Versatile Applications

Used in diverse applications including prototype production with resin and wood, design mockups, and educational materials.

The separate control panel design offers flexible layout arrangements for a variety of installation environments.

- Product development prototyping

- Design mockup production

- CNC operator training

- R&D prototyping

Development of TLM Series

Building on the technology cultivated with the TRW Series, we developed the TLM Series for light metal machining.

You can choose between the TRW Series for resin machining and the TLM Series for metal machining according to your needs.

TRW Series Features

Outstanding features of Table-top NC machining center specialized for resin machining

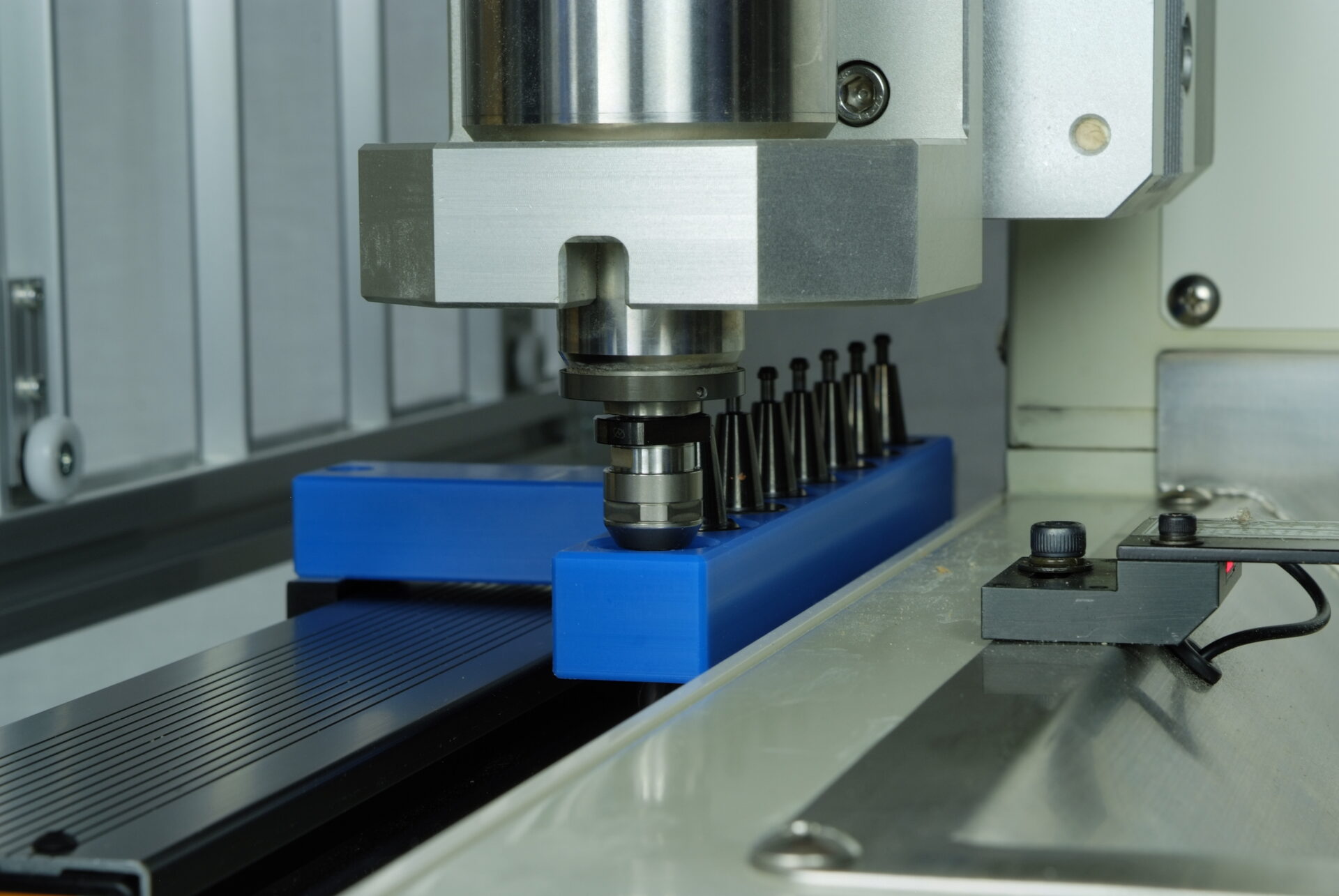

Flexible Control Panel Placement

Separate control panel allows flexible layout arrangements for a variety of installation environments. Makes effective use of work space.

Air Chuck

Air chuck enables one-touch workpiece loading and unloading. Significantly reduces setup time and improves work efficiency.

Spindle Tilt Mechanism

Adopts a spindle tilt mechanism with easy-to-understand machine movement and high maintainability. Structure is easy to understand even in educational settings.

Compact Design

Compact design with machine body W760 × D810 × H840mm. Desktop size enables easy installation even in limited spaces.

ATC – Automatic Tool Changer

Automatically changes 8 tools, enabling rough to finish machining in a single program.*Optional

Ideal for Education and Training

Control panel is comparable to standard NC machine tools for easy operation, and can be used for CNC operator training.

5-Axis Simultaneous Control

5-axis models enable 3D machining with simultaneous 5-axis control. Handles prototyping of complex shapes.*Optional

Diverse Axis Configurations

Choose the optimal model from 3-axis, 4-axis, or 5-axis configurations according to your application.

Compatible Materials

Table-top NC machining center specialized for resin and wood machining

Resin/Plastics

Primary Materials

- Various resins including ABS, acrylic, and chemical wood

- Extensive prototyping track record

- Ideal for design mockups

- Proven track record in educational settings

Wood

Compatible Material

- Design mockup production

- Wooden component machining

- Proven track record in R&D applications

For Metal Machining Applications

The TRW Series is specialized for resin and wood machining.

For aluminum and other light metal machining, please see the TLM Series.

For other materials, please feel free to contact us.

Detailed Specifications

Detailed specifications for each model

| Item | TRW-5 (5-axis) | TRW-4 (4-axis) | TRW-3 (3-axis) |

|---|---|---|---|

| Simultaneous Control Axes | 4-axis | 3-axis | |

| Power Supply | Three-phase 200 to 230 VAC (50/60Hz) Voltage fluctuation: within +10%, -15% |

||

| Dimensions | Machine body: W760 × D810 × H840mm Shutter enclosure: W860 × D875 × H1,070mm Control panel: W485 × D420 × H750mm |

||

| Total Equipment Weight | 250-300kg *Varies depending on axis configuration and options |

||

| Stroke (Linear Axes) |

X-axis: 500mm Y-axis: 170mm Z-axis: 250mm |

X-axis: 420mm Y-axis: 170mm Z-axis: 250mm |

X-axis: 170mm Y-axis: 170mm Z-axis: 100mm |

| Stroke (Rotary Axes) |

B-axis: ±100° C-axis: ∞ |

Select B-axis or C-axis | — |

| Spindle | MAX 6,000 min⁻¹ (Variable with S command) | ||

| Main Spindle | AC servo motor (Max 400W) | ||

| Tools | Shank diameter: φ1-φ6 | ||

| Collet | BT5 equivalent | ||

| Machinable Materials | Resin, Wood | ||

| Chucking | 3-jaw air chuck | Vise | |

| Workpiece Size | □80 × t100mm | W200 × D150 × t200mm | |

| Control Unit | Mitsubishi Electric Numerical Control (CNC) M80V | ||

| Display | 10.4″ Touch Panel | ||

*Specifications are subject to change without notice.

*For detailed specifications and case studies, please feel free to contact us.

TRW Series Application Scenarios

Active in diverse fields from education to R&D

Educational Institutions

Ideal for CNC operator training at universities, technical colleges, and vocational schools. Control panel is comparable to standard NC machine tools, enabling acquisition of practical skills. Compact size allows easy installation even in training rooms.

- Practical NC operation skill acquisition

- Integrated learning with CAD/CAM

- Installation possible in limited spaces

R&D

In corporate R&D departments and university research laboratories, the TRW Series enables rapid prototyping from initial concepts. The air chuck reduces setup time, accelerating trial-and-error cycles and streamlining development processes.

- Rapid prototype production

- Handles complex shape prototyping

- Accelerates R&D processes

Design and Mockup Production

Ideal for product design mockup production. Can quickly produce design verification models using resin and wood. Separate control panel design makes it suitable for design office use.

- Streamlined design verification

- High-quality finish

- Immediate prototyping in design offices

Small-Lot Production

Can be used for small-lot resin component production such as jigs and specialized parts. When combined with ATC option, it enables unmanned operation and improves production efficiency.

- Jig and specialized part production

- Handles small-lot production

- Efficiency through unmanned operation

Contact Us About

TRW Series

Product details, demo requests, quotations, sample machining, and more

Our expert staff will be happy to assist you