TLM Series

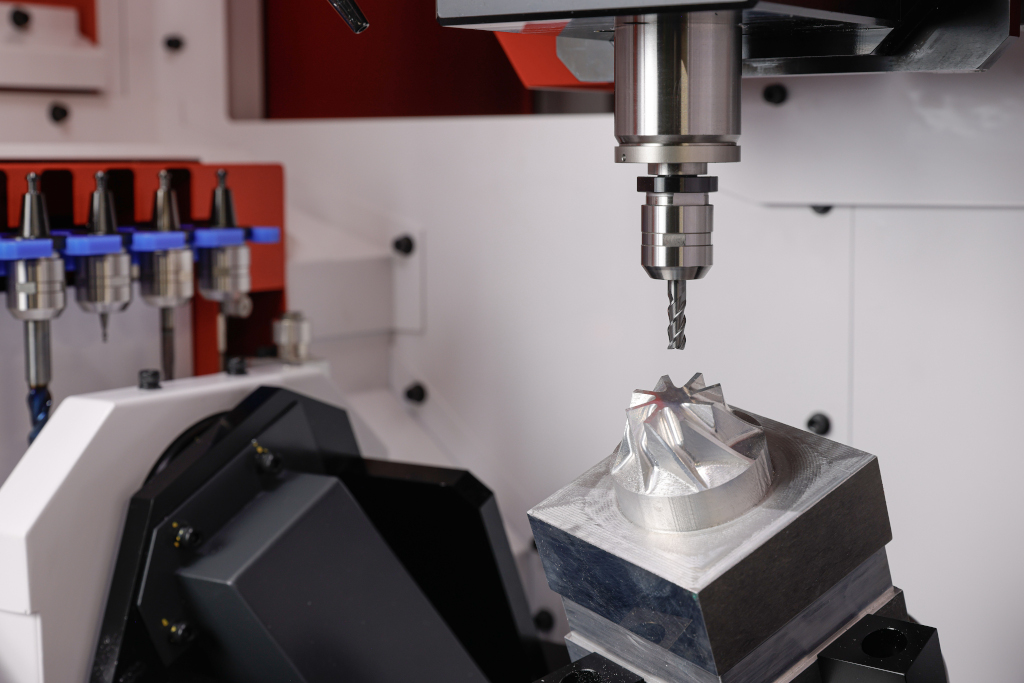

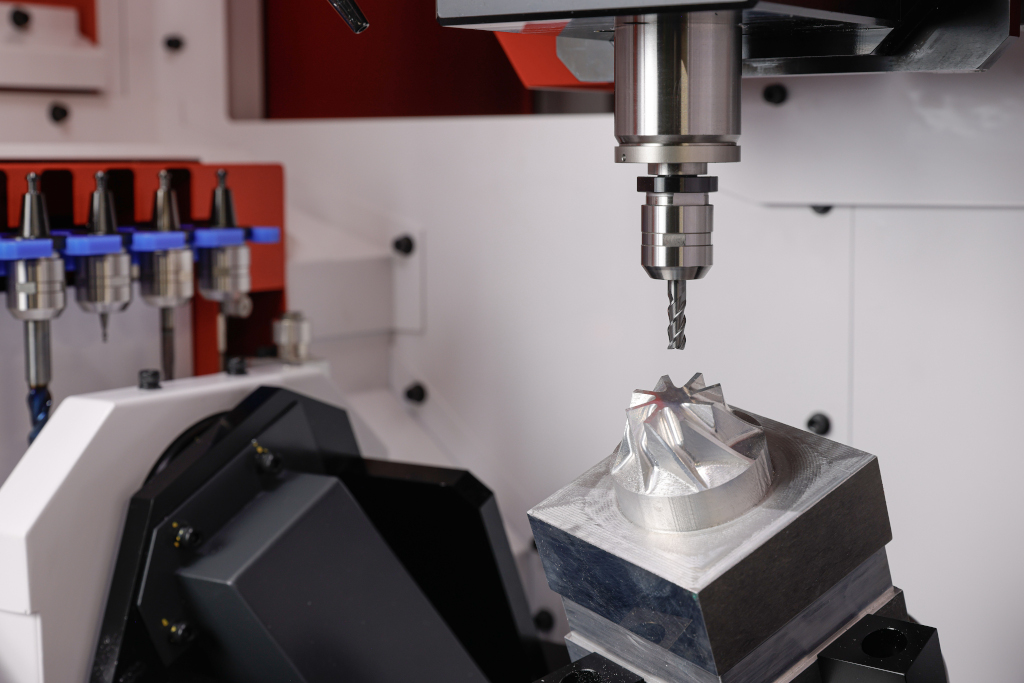

Table-top NC Machining Center for Light Metal Machining

Our newly developed high-speed spindle (MAX 12,000 min⁻¹) and oil mist system

enable precision aluminum machining in a Table-top footprint.

TLM Series Development Background

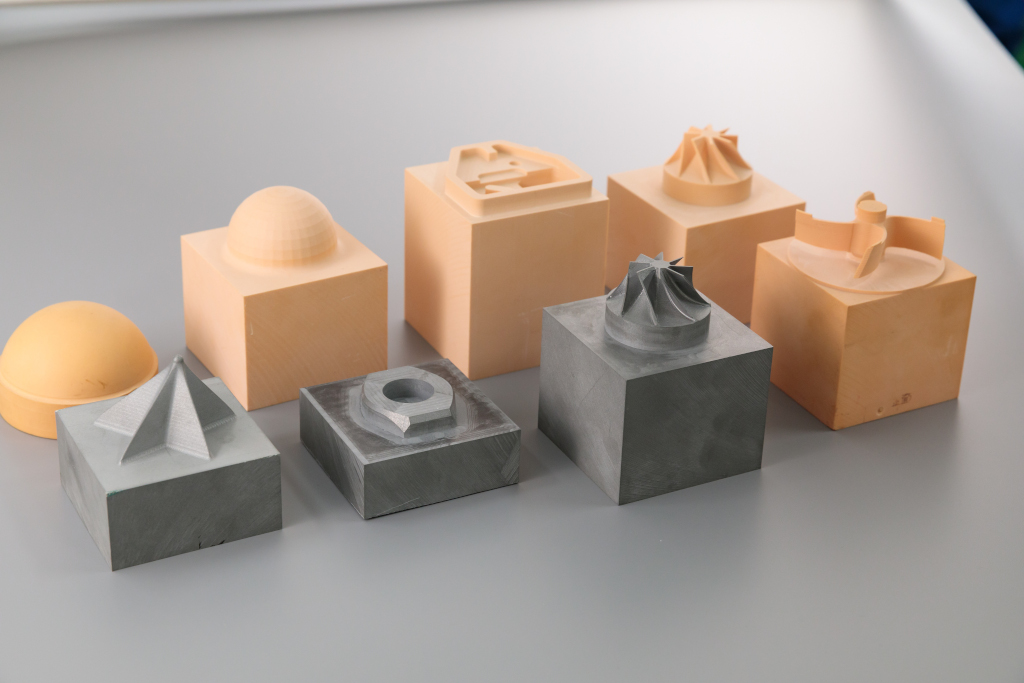

Achieving light metal machining based on years of resin machining technology

Extensive Track Record in Resin and Wood Machining

The “Takumi-kun” has been adopted by numerous customers, primarily in educational institutions and research laboratories.

We have accumulated extensive know-how in resin and wood machining.

Evolution to Light Metal Machining

In response to customer requests for aluminum machining, we developed a high-speed spindle and oil mist system.

By incorporating these developments into the TLM Series, we achieved light metal machining capability.

- High-speed spindle MAX 12,000 min⁻¹

- Oil mist compatible

- Professional metal machining in Table-top size

Demonstrated at MECT 2025

Demonstrated aluminum machining at “MECT 2025”, Japan’s largest machine tool exhibition.

Received significant interest from metal machining professionals.

TLM Series Features

Outstanding features of Table-top NC machining center for light metal machining

Space-Saving Design

Compact design with machine body W1,230 × D980 × H1,050mm. Table-top size enables easy installation even in limited spaces. Ideal for design offices and laboratories.

High-Speed Spindle

High-speed rotation of MAX 12,000 min⁻¹ achieves smooth machining even with small-diameter tools. Ideal for precision aluminum machining.*Optional (Standard 6,000 min⁻¹)

Table Tilt Mechanism

Adopts an effective chip discharge mechanism, balancing efficient machining with easy cleaning.

Mist Compatible

Environmentally conscious semi-dry machining is achievable with oil mist. Contributes to high-precision machining and extended tool life during metal processing.*Optional

Chip Tray

Chips are discharged into tray for easy cleaning. Designed for excellent maintainability.

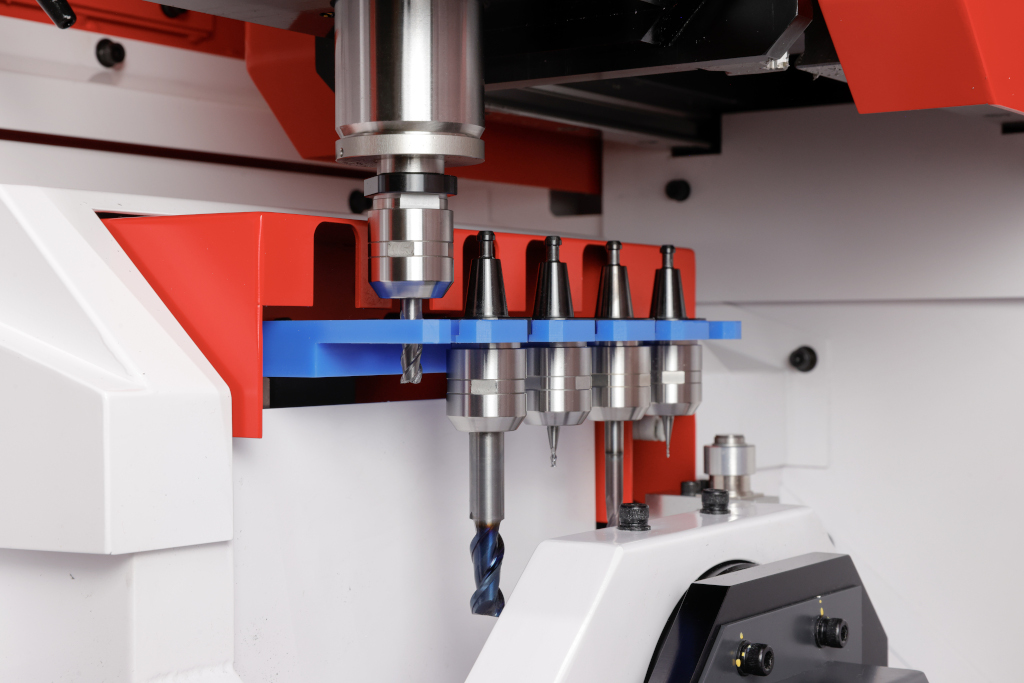

ATC & Automatic Tool Length Measurement

Equipped with ATC (Automatic Tool Changer) and automatic tool length measurement functions. Supports unmanned operation.*Optional

Ideal for Education and Training

Control panel is comparable to standard NC machine tools for easy operation, and can be used for CNC operator training.

5-Axis Simultaneous Control

5-axis models enable 3D machining with simultaneous 5-axis control. Handles prototyping of complex shapes.*Optional

Compatible Materials

Table-top NC machining center compatible with wide range of materials

Aluminum

Newly Developed!

- Smooth finish with 12,000 min⁻¹ high-speed spindle

- Stable machining with oil mist compatibility

- Ideal for prototype parts and precision machining

- Handles complex 3D shapes

Resin/Plastics

Previously Supported

- Various resins including ABS, acrylic, and chemical wood

- Extensive prototyping track record

- Proven track record in educational settings

Wood

Previously Supported

- Design mockup production

- Wooden component machining

- Proven track record in R&D applications

Materials That Cannot Be Machined

The TLM Series is not compatible with machining hard metals such as steel and stainless steel.

Compatible materials are aluminum, resin, and wood.

For other materials, please feel free to contact us.

Detailed Specifications

Detailed specifications for each model

| Item | TLM-5 (5-axis) | TLM-4 (4-axis) | TLM-3 (3-axis) |

|---|---|---|---|

| Simultaneous Control Axes | 4-axis | 4-axis | 3-axis |

| Power Supply | Three-phase 200 to 230 VAC (50/60Hz) Voltage fluctuation: within +10%, -15% |

||

| Dimensions | Machine body: W1,230 × D980 × H1,050mm | ||

| Total Equipment Weight | 600-700kg *Varies depending on axis configuration and options |

||

| Stroke (Linear Axes) |

X-axis: 340mm / Y-axis: 200mm / Z-axis: 200mm | ||

| Stroke (Rotary Axes) |

A-axis: +120° / -45° C-axis: ∞ |

Select A-axis or C-axis | — |

| Spindle | MAX 12,000 min⁻¹ (Optional) Standard: 6,000 min⁻¹ (Variable with S command) |

||

| Main Spindle | AC servo motor (Max 400W) | ||

| Tools | Shank diameter: φ1-φ10 | ||

| Collet | BT6 equivalent | ||

| Machinable Materials | Aluminum, Resin, Wood | ||

| Chucking | 3-jaw scroll chuck | Vise | |

| Workpiece Size | □80 × t100mm | W200 × D150 × t200mm | |

| Control Unit | Mitsubishi Electric Numerical Control (CNC) M80V | ||

| Display | 10.4″ Touch Panel | ||

*Specifications are subject to change without notice.

*For detailed specifications and case studies, please feel free to contact us.

Demonstrated at MECT 2025

Well received at Japan’s largest machine tool exhibition

Numerous Inquiries from Metal Machining Industry

At Mechatronics Technology Japan 2025 (MECT 2025) held in 2025, we demonstrated aluminum machining with the TLM Series.

We received high praise from many visitors for the performance that achieves professional metal machining despite the Table-top size.

Visitors particularly praised its compact design, enabling installation in limited spaces and facilitating immediate, in-office prototyping. These advantages generated numerous inquiries.

Contact Us About

TLM Series

Product details, demo requests, quotations, sample machining, and more

Our expert staff will be happy to assist you